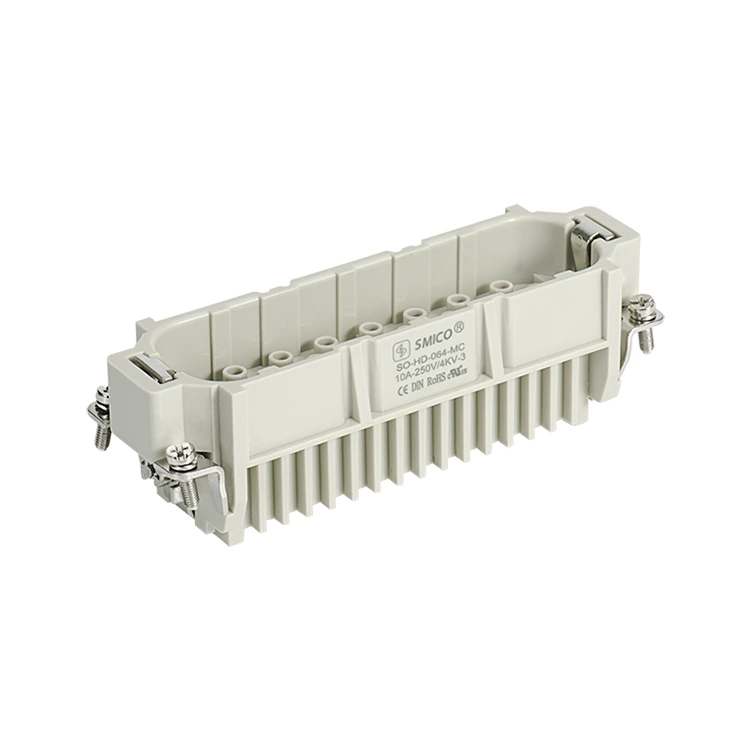

HD-064-FC 64Pin 10A 250V Crimp terminal Female Rectangular Waterproof Rectangle Heavy Duty Connector For Engineering Automation

- Brand:

- SMICO

- Standard:

- IEC-61984

- Number of contacts:

- 64+PE

- Working Voltage:

- 250V

- Working current:

- 10A

- Material:

- Polycarbonate

- Terminal:

- Screw terminal

- Wire Gauge:

- 0.4-2.5mm²(AWG26-14)

- Certification:

- UL CUL CE ROHS

- Screw terminal tingtening:

- 0.5Nm

- Pollution degree:

- 3

Product Description

Heavy-duty connectors, also known as HDC heavy-duty connectors, aviation plugs, are widely used in construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, robots, rail transit, hot runners, electricity, automation, etc. that require electrical and signal connections In the device.

64 Poles+PE,10A,crimp terminal male insert

| Inserts | Suitable Shell:3AHood/Housing |

| Number of contacts | 64+PE |

| Electrical data acc. to EN 61 984 | |

| Rated current | 10A |

| Rated voltage onductor | 250V |

| Rated impulse voltage | 4KV |

| Polluition degree | 3 |

| Pollution degree 2 also | 16A 250V 4KV 3 |

| Rated voltage acc. to UL/CSA | 600V |

| Insulation resistance | ≥1010Ω |

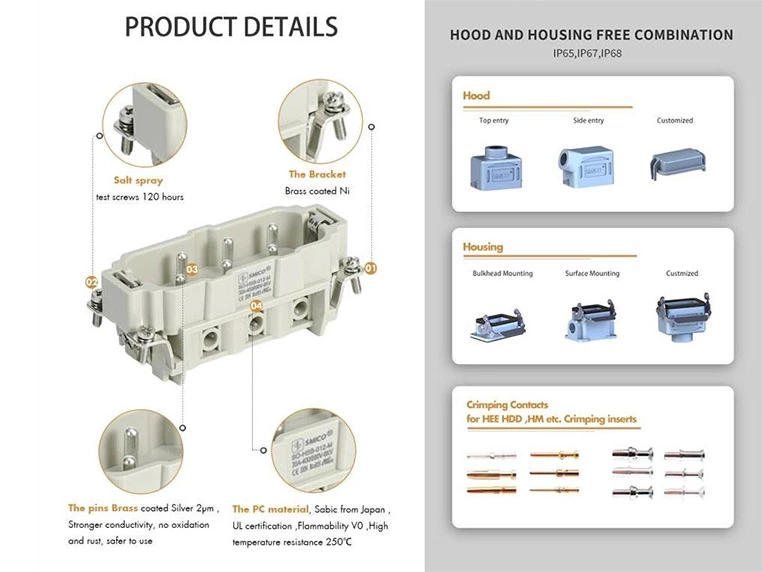

| Material | polycarbonate |

| Limiting temperatures | -40℃...+125℃ |

| Flammability acc. to UL 94 | V0 |

| Mechanical working life(mating cycles) | ≥500 |

| Contacts | |

| Material | copper alloy |

| Surface | hard-gold plated |

| hard-silver plated | |

| Contact resistance | ≤1mΩ |

| Wrie gauge | 0.14-2.5mm2 |

| AWG | 26-14 |

The function of the heavy-duty connector

1. Electrical insulation between connectors to avoid interference between signals.

2. Fix the position of the connector, which is conducive to plugging and unplugging and the stability of the position.

3. Provide mechanical protection and support for the insert body.

4. Separate the connector from the application environment, reduce environmental pollution and corrosion of the connector, and extend the service life of the connector.

The advantages of heavy-duty connectors

1. Realize pre-installation, pre-installation of a large number of complicated circuits, which can greatly improve the efficiency of equipment installation and reduce the rate of wiring errors.

2. The heavy-duty connector provides a highly integrated connection, and the abundant combination methods maximize the effective utilization of the equipment space.

3. Heavy-duty connector The connector conveniently and efficiently realizes the modular structure of each functional template block in the equipment, so that the equipment can be transported, installed, maintained and repaired conveniently and safely. Connectors are widely used in the field of power transmission and distribution.

4. The high protection level (IP65, IP68) provided by the heavy-duty connector is incomparable to the advantages of the equipment connection system in the harsh environment. Provide effective protection in harsh environments such as sand, dust, rain, cold, ice and snow, and oil pollution.

heavy-duty connector wiring method

1. Loosen the screw with a screwdriver, put the wire into the side hole of the insert, and then tighten the screw.

2. To install the upper shell of the heavy-duty connector, use a screwdriver to unscrew the fixing screws of the insert, put the insert into the upper shell, and then tighten the fixing screws.

3. For the installation of the lower shell of the heavy-duty connector, use the same method to fix the lower shell, and insert the upper shell and the lower shell of the inserted body into each other.

Heavy Duty connector Screw termination with wire protection,Suitable for power supply applications,Termination with standard screw driver