Hard ware forged eye bolt for dead end insulators in electric power lines or overhead lines fittings

- Supply Ability:

- 200000/Month

Hard ware forged eye bolt for dead end insulators in electric power lines or overhead lines fittings

Description:

SMICO‘s forged eye bolt is an overhead power line accessory that is used for connecting dead end insulator in an overhead line. The power line fitting is widely used on wooden poles whereby it can connect the overhead line or even dead end insulator.

It can also be referred to as the drop forged eye bolt or just forged eyebolt.

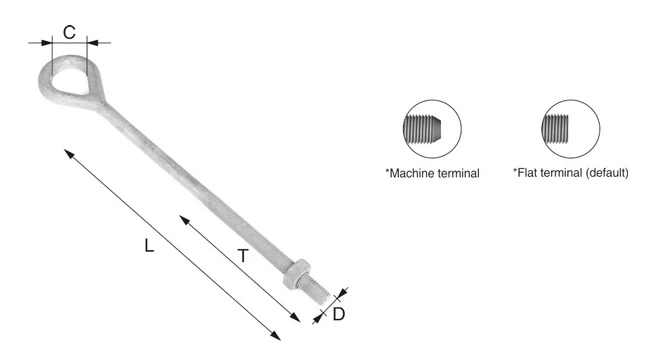

Forged eye bolts come in two main designs. These are the oval eye bolts and the round eye bolts. The forged oval eye bolt has a thimble. When you connect the eye bolt to the clevis or a dead end insulator, this thimble will remain locked.

Forged eye bolts are usually assembled with square and hex nuts. The nut is then fastened on the eye bolt once it has gone across the wooden pole.

Our forged eye bolts are made of galvanized steel and are not welded at any point. This means that you can be sure about the strength of this electric power line accessory.

The galvanization is there to protect against corrosion. Water and other chemicals won’t have negative effects on these power line fittings.

Applications:

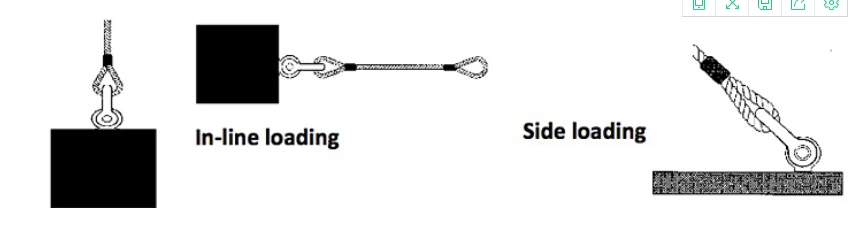

Typically, installation of eye bolts is on materials such as steel or wood poles, and you use nuts to fasten them.

Application of Eye Bolt

Eye bolt is a type of steel fasteners that widely used in numerous industrial applications for lifting, rigging, anchoring, pushing, or pulling.

There are various types and materials of eye bolts for different applications, so it is very important to understand and choose the right product.

There are various types and materials of eye bolts for different applications, so it is very important to understand and choose the right product.

1.What is an eye bolt?

An eye bolt is a type of mechanical fastener having a threaded shaft and a ring. It is used for attaching an eye to the structure. This way, any rope, shackles, or cable can be secured to the bolt. The lifting eye is created to help the crane attach to the machinery. This is why lifting eyes for special purposes come to use for a safe working load.

2.Low Strength Eye bolts

Low strength eye bolts are created from a bar length having a diameter of a thread (nominal). The unthreaded portion of this bar is where the ring originates. The low strength eye bolts can easily carry the axial loads. However, these types should not be utilized for off axis loads. The opening end can be welded which can cause it to break.

3.High Strength Eye Bolts

Eye bolts of high strength have forged rings including a shoulder (substantiated). With the help of a shoulder, much of the off-axis load is supported. This is significantly important in the application where multiple eyes for lifting are attached to slings having multiple legs. Therefore, high strength eye bolts endure more weight than low strength eye bolts and hence are used in lifting applications.

For purposes like lifting machinery, the eye bolt has the chances to get screwed directly in the allocated structure’s hole. In this regard, a fully threaded eye bolt is needed that has threads till the shoulder. If a hole is utilized for the insertion of the eye bolt, and nut is used to fasten it, a shank can be of great help. The shank is the unthreaded region of the shaft that is underneath the shoulder. It gives a better load transfer on the hole surface. This makes it resilient to fracture in case of overloading.

4.Eye bolt Materials

Eye bolts are composed of a variety of materials – the most probable are alloy steel, stainless steel, and carbon.

The stainless steel eye bolts are resistant to rust. This is made possible because of the core material chromium, iron, manganese, nickel, molybdenum, silicon, and some quantity of carbon as well

1.Are you a manufacturer? If yes ,where is your factory?

Yes ,we are a manufacturer.Our factory & head office is located in Liushi Town,Yueqing City,the China Electrical City. Have conveniently traffic 25km respectively from Wenzhou airport and railway station,and 5km from 104 national road freeway.

2.How can I place an order to you?

You should supply us the detailed technical specifications or SLD(single line diagram)or relative drawings firstly email,wechat,whatsapp,telephone..etc. You can contact any of our sales persons in any time for quotation &further communication .

3.What is your payment terms?

Our payment methods are flexible and convenient, such as PayPal, telegraphic transfer, etc.

4.Do you accept OEM&ODM?

Yes.

5.Where is your main market? How many percentage for your international business in your annual sales?

Our main market is Europe,North South America and South-east Aisa,Exports accounted for over 80%.

6.Are you supply sample?

Yes,we can supply.

7.What’s you delivery time?

Usually 15-30 days.It depends your order quantity.