Wire rope thimble for supporting and protecting the ADSS cable

- Standard:

- ISO 1461 ISO 9001

- Supply Ability:

- 200000/Month

Wire rope thimble for supporting and protecting the ADSS cable

Description:

SMICO‘s Wire rope thimble,also known as the cable thimble or stay wire thimble, is utilized for working as an interface on pole band to connect to the guy grip. The guy thimble is extensively utilized for the electric power line or a dead end line. In addition to that, the cable thimble generally connects with the already formed tension clamp for supporting and protecting the ADSS cable.

The cable thimble is generally used as an accessory. Moreover, it is also utilized on a stay rod for connecting the guy wire. The structure of a guy thimble is quite comprehensive and simple. The guy thimble is bent with the help of an internal contour so that it can fit in multiple strand sizes. Moreover, the smooth channel is for preventing the concentration of stress on a single point.

The raw material used in a guy thimble is steel sheet having altering thickness and the punching machine cuts the steel into two ends at specific angles. The thimble has no sharp or protruding ends and the sheet is bent to a crescent shaped body. It is gone through galvanization according to the standards set by ISO 1461. The finished surface is free from burrs and is smooth.

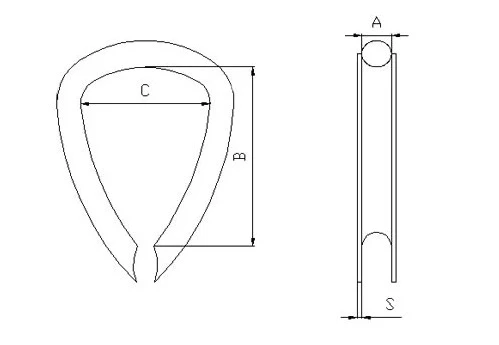

| Modle | Strand size Inch | Dimension(mm) | Thickness(mm) | Approximate Shipping Weight Kg/100pcs | Standard PKG QTY/Carton |

||

| A | B | L | |||||

| G0750-38 | 3/8 | 20 | 30 | 55 | 3 | 10 | 200 |

| G0750-12 | 1/2 | 25 | 40 | 80 | 3 | 12.4 | 150 |

| G0750-58 | 5/8 | 35 | 50 | 90 | 3 | 15 | 150 |

Wire Rope Thimble for Steel Wire – The Ultimate Guide

1.What is a guy thimble?

A Wire rope thimble terminates the electrical connection or wire professionally. It minimizes any leakage in the current to offer protection against electrical failures and overheating. It does so as it protects from improper terminations of connections. Moreover, it is necessary to utilize the size and kind of guy thimble while using it for different connections.

2.Where is it used?

A high risk of crushing is present when a professional is trying to connect a wire to other components. The wire rope thimble saves the rope through connecting to the eye and provides more support. In addition, the wire rope thimble also makes a natural curve and guides the eye of the wire. You can get wire rope thimbles in various materials and strengths. The wire rope thimble has a radius in a way that adds to the strength of the ropes. It also finds it uses in different wire rope grips, turnbuckles, and shackles. The wire rope thimble has different components positioned at certain angles. It is highly important so the anchor has an efficient performance.

3.What are the types of wire rope thimble?

A cable thimble or a stay thimble is available in standard duty fabrication in light and heavy duty style.

If you want a heavy duty performance, then you should choose a heavy thimble wire for rope. You can get both styles in a zinc-plated metal usable in all types of environment.

If there is a wet environment such as marine application, you can get the rope wire thimble in stainless steel.

4.What are the specs of wire rope thimble?

There are different diameters and dimensions available in the steel sheets for a wire rope thimble. The steel sheet is cut in different angular ends with the help of a punching machine. There are no sharp edges of wire rope thimble.

The main body of the rope wire thimble has a crescent shape. The surface undergoes a special treatment process for hot dip galvanization in regard to ISO 1461. There are no rough edges on the surface which has undergone galvanization.

5.How to install a wire rope thimble?

You need to collect all equipment required to install a guy thimble. You need to select the material wisely as the requirements for the installation of the steel cable thimble are different. It means that the thimble in stay set might have varied needs. You will need to fix the base securely at the points for the fixture. The fixing points are used in connecting the anchor points and the turnbuckles. You do not need to stress the pole structure of the stainless steel wire rope thimbles. For that, locate the anchor of the thimble eyes a little far from the base of the pole.

You will need to remove the shipping pin and the screw from below and then the top one by one. After that, slide the guy plate at the top with the guy support from the pole. Put the components back in reverse order. You will need to screw the locks correctly so you are sure that there are strong connections that are not mountable.

You will need the help of other professionals to raise the pole in an upright position and then make it stand on the base plate. You will need to attach the sets at the bottom with the anchors of the turnbuckles. It is important to make them as tight as you can before you proceed to analyse the vertical.

1.Are you a manufacturer? If yes ,where is your factory?

Yes ,we are a manufacturer.Our factory & head office is located in Liushi Town,Yueqing City,the China Electrical City. Have conveniently traffic 25km respectively from Wenzhou airport and railway station,and 5km from 104 national road freeway.

2.How can I place an order to you?

You should supply us the detailed technical specifications or SLD(single line diagram)or relative drawings firstly email,wechat,whatsapp,telephone..etc. You can contact any of our sales persons in any time for quotation &further communication .

3.What is your payment terms?

Our payment methods are flexible and convenient, such as PayPal, telegraphic transfer, etc.

4.Do you accept OEM&ODM?

Yes.

5.Where is your main market? How many percentage for your international business in your annual sales?

Our main market is Europe,North South America and South-east Aisa,Exports accounted for over 80%.

6.Are you supply sample?

Yes,we can supply.

7.What’s you delivery time?

Usually 15-30 days.It depends your order quantity.