TTD151F weatherproof UV black thermoplastic insulation piercing connector

- Conductor Range:

- 25-95/(2.5)6-35mm²

- Standard:

- NFC 33 020, ANSI C119.5, EN 50483-4

- Supply Ability:

- 500000/month

- Bolt:

- 1

- Tightening Torque:

- 13±1NM

- Color:

- Black or customized

- Suitable Cable Use:

- XLPE, PE or PVC

- Packaging Details:

- 200pcs/ctn 21kg 475x270x400mm

TTD151F weatherproof UV black thermoplastic insulation piercing connector

Description:

SMICO TTD151F Insulation Piercing Connectors are made for service connections. The blades of the Service Insulation Piercing Connector are made of tin-plated copper or aluminium alloy allowing connections to aluminium and/or copper stranded conductors. These bodies are made of plastic with fiberglass allowing high resistance to its environment but also offering superior mechanical properties. A single torque control nut draws the two parts of the connector together and shears off when the teeth have pierced the insulation and made contact with the conductor strands.Ease of installation has been combined with excellent mechanical, electrical and environmental characteristics to provide a connector capable of terminating aluminium or copper stranded conductors. All of our insulation piercing connectors are designed and tested to fit the majority types of cables made in accordance with the European Standard HD 626, regardless of whether cables are insulated with XLPE, PE or PVC. The products are tested according to national specifications such as NFC 33 020, ANSI C119.5 and the European standard EN 50483-4.

These standards include tests to verify reliable operation even in the harshest environments:

- Designed for installation from –20 °C up to +50 °C

- No limitation of mechanical loads for main and branch conductors

- Shear head forces are adapted to the required contact forces for each application (main, service, lightning)

- Voltage withstand to 6 kV in a 30 cm water bath

- No change in contact resistance and temperature after overloads and load cycling

- Voltage withstand to 6 kV in metallic balls after heavy weathering exposure (UV-light, humidity and temperature cycling)

- Corrosion resistance of the metal parts has been proven in the salt fog chamber and wet SO2 gas chamber

Key Features:

- Range-taking

- Suitable for XLPE, PE or PVC conductors

- Waterproof

- Captive and flexible end caps

- All components are solid and fixed in place

- Equipped with shear head to ensure a reliable tightening torque

- Operating temperature -55°C to +55°C

- Installation temperature -20°C to +55°C

- Can be installed on energized main if not under load

Application Guide

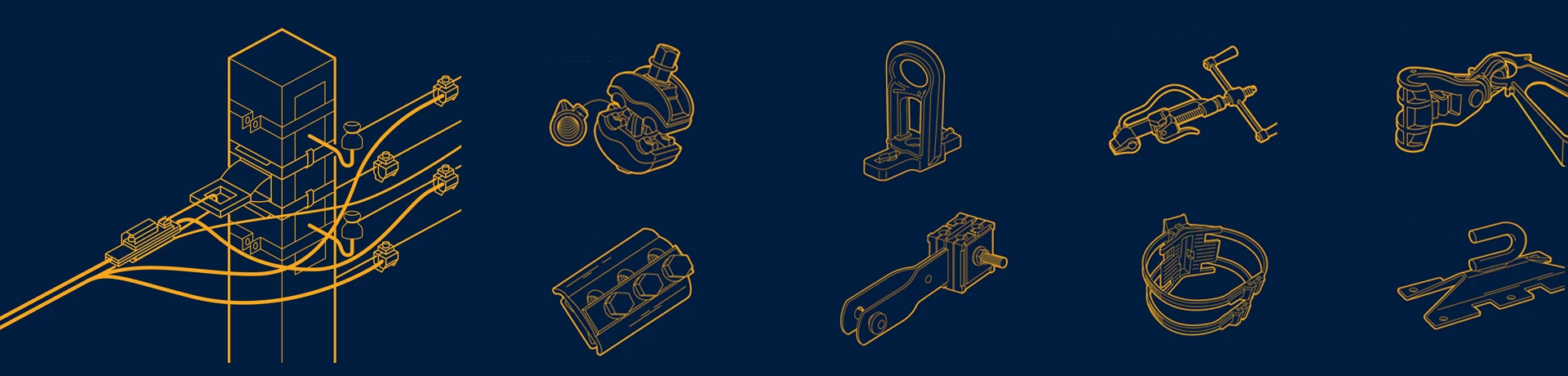

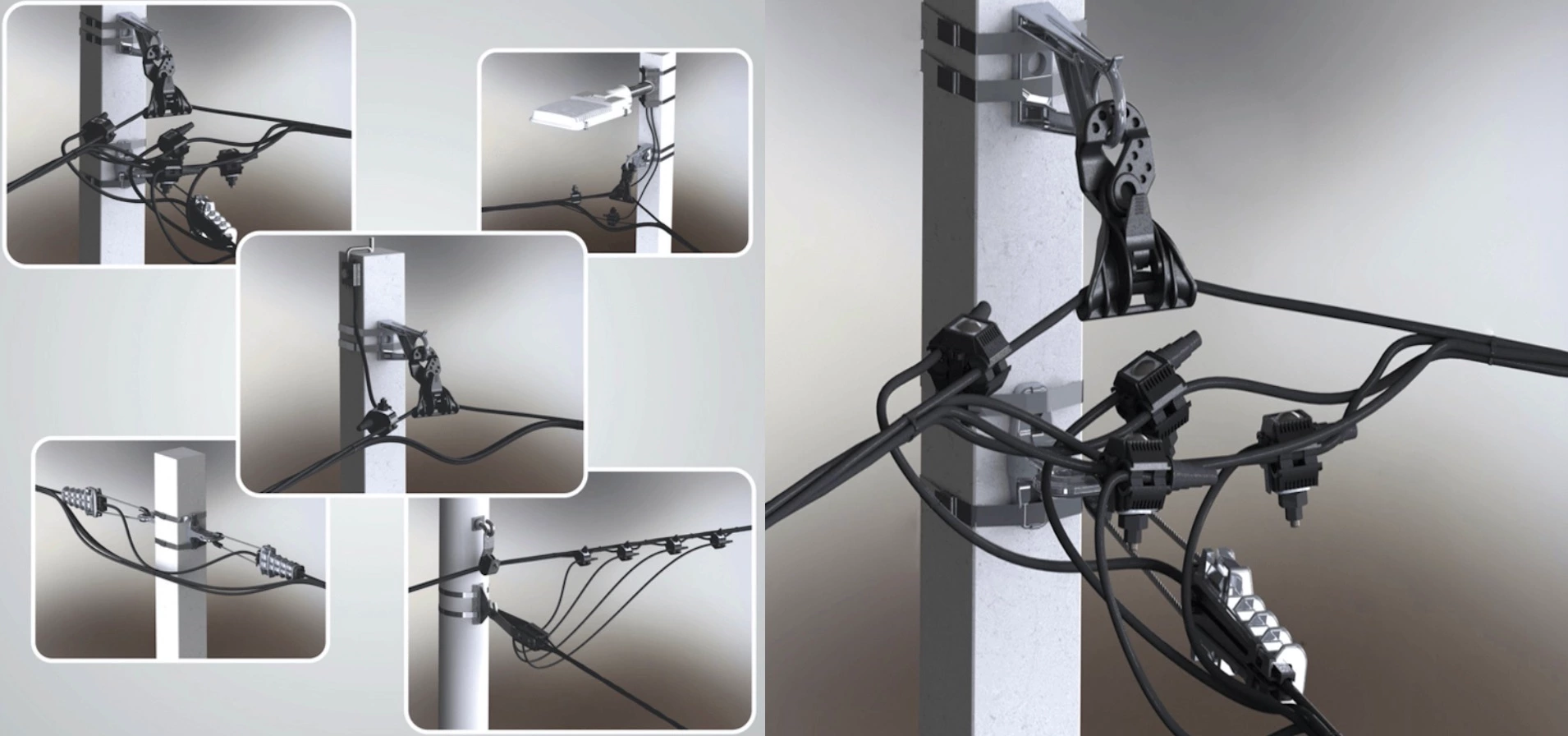

1. STREET LIGHT CONNECTIONS

In this application, insulation piercing clamp are generally used to tap the main ABC Cable and connecting it to a service line that powers streetlights or other applications.

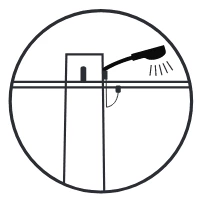

2.DISTRIBUTION BOX CHARGING CONNECTION

These insulated piercing connector are used to tap the main ABC Cable Line to charge Low Voltage Distribution Boxes which are further connected to different applications such as residential connections, street lights, etc. SMICO Low Voltage Distribution Boxes can provide up to 9 outgoing connections for each incoming line.

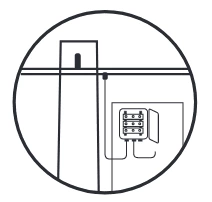

3.JUMPER CONNECTION

These IPC are generally used with the same size of cable on each side to facilitate T-Connections (90° turns) or any other high angle turn.

4.TAP OFF/MULTI-TAP CONNECTION TO HOUSEHOLDS

These insulation piercing connector are used to tap the main ABC Cable and bring power to households. Using the Multiport IPC, a one-tap connection from the mainline can be used to bring connections to multiple households.

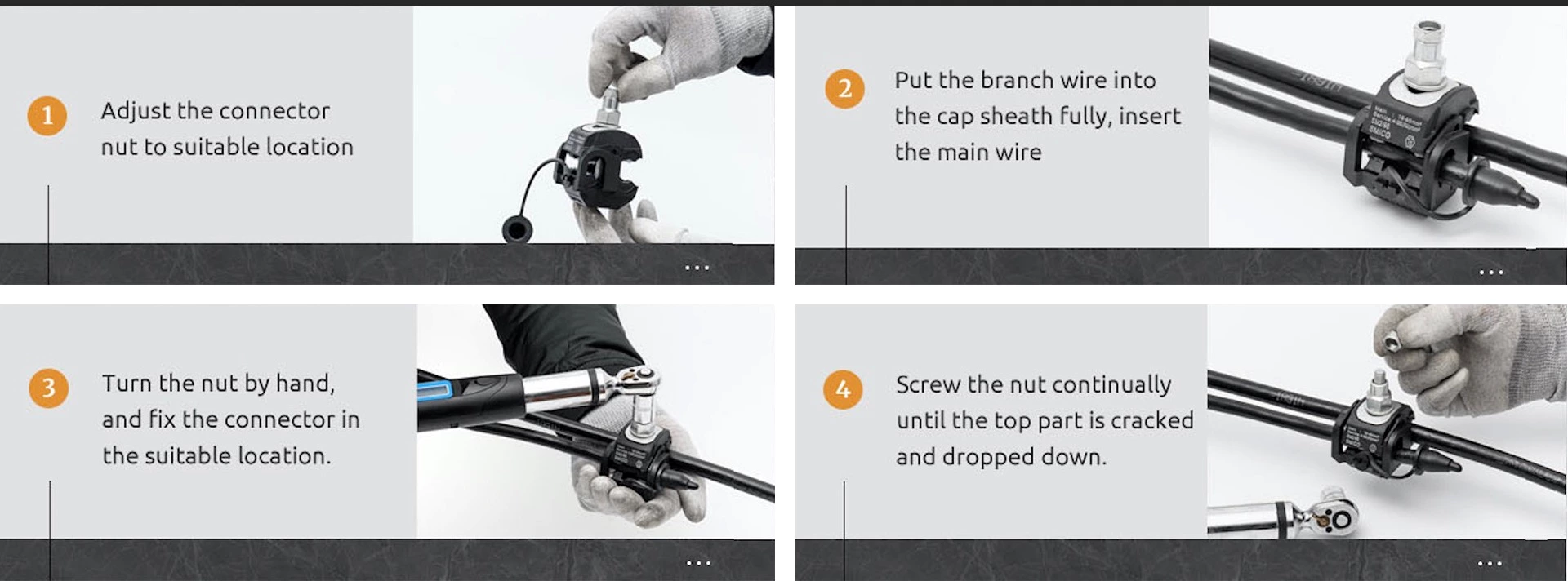

How to install SMICO Insulation Piercing Connectors (IPC) for Aerial Bundled Cables

| Modle | Main | Tap | No.Bolt |

| IPC3.1 | 16-95 | 10-25 | 1 |

| IPC3.2 | 70-95 | 70-95 | 1 |

| IPC3.3 | 120-185 | 16-25 | 1 |

| IPC3.4 | 70-185 | 70-185 | 2 |

| TTD121F | 25-95 | 2.5-25 | 1 |

| TTD151F | 25-95 | (2.5)6-35 | 1 |

| TTD201F | 35-95 | 25-95 | 1 |

| TTD281F | 50-185 | 6-35 | 1 |

| TT2D82F | 25-95 | 25-35 | 1 |

| TTD451F | 95-240 | 95-240 | 2 |

Question: What type of cables can I connect with SMICO's SM2X95 Service Insulation Piercing Connectors?

Answer: SMICO SM2-95 Service Insulation Piercing Connectors are designed for connections between LV-ABC (low voltage aerial bundled conductor) and service or main cable. They are ideal to extend from the primary utility facility to private property.

Question: What tool should be used to install the Service Insulation Piercing Connectors?

Answer: The installation of these connectors doesn't require any specific tool, only a standard wrench with the appropriate hexagonal sockets.

Question: How do installers know that the right tightening torque has been applied to the Service Insulation Piercing Connectors during installation?

Answer: These connectors are equipped with a shear bolt head. The shear bolt head is designed to break once the installer reaches the recommended tightening torque. This SMICO technology ensures that the optimal contact force is applied to the conductors to minimize connection resistance.

Question: Do I need to strip the cable's insulation before installing the Service Insulation Piercing Connectors?

Answer: No, our Service Insulation Piercing Connectors are equipped with tin-plated copper or aluminum alloy blades which will pierce the insulation of the cables and establish a reliable electrical contact between the conductors.

Question: Is there a risk of electrocution from touching exposed metallic parts of the Service Insulation Piercing Connectors?

Answer: No, our engineers specially designed these connectors making sure that all exposed metallic parts are out of potential reach during and after connector installation.