Characteristics And Processing Status Of Power Fittings

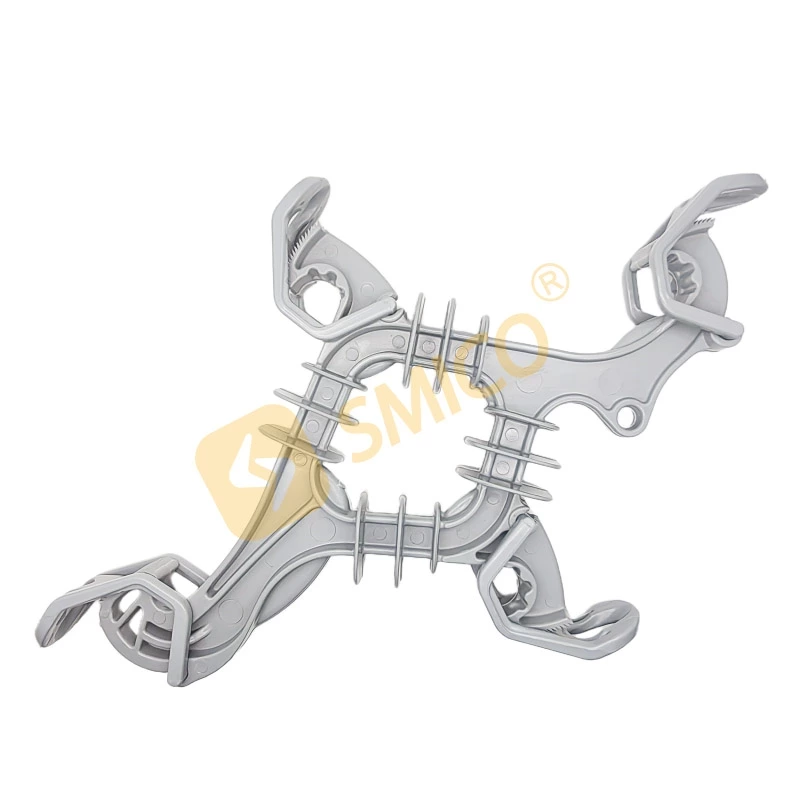

Suspension Clamp is mainly used for transmission equipment in overhead power lines, substations and power plants, including connection fittings, contact fittings, protective fittings, busbar fittings, suspension clamps, tension clamps and fasteners. The shape of power fittings is not complicated, and most of them are straight. The materials used are forgings, stampings, stainless steel parts, aluminum parts, ductile iron parts, gray cast iron parts and malleable cast iron parts.

Most of the power fittings are exposed to the atmosphere and suffer from atmospheric corrosion in different regions and climates, which puts higher requirements on the corrosion protection of fittings. In particular, for ferrous metals other than stainless steel and gray cast iron, hot-dip galvanizing is currently widely used for corrosion protection, that is, the fittings are immersed in a molten zinc tank, and a continuous and protective zinc-zinc-iron compound layer is attached to their surface. The basic production process is as follows:

Alkaline degreasing → pickling and rust removal → water washing → flux immersion plating → drying → hot-dip galvanizing → water cooling

A large amount of waste acid, waste water and waste residue are generated during the treatment process, which seriously pollutes the environment. The quality of the zinc coating of general power fittings is above 460g/㎡ (about 65μm thick), which is equivalent to 165h of neutral salt spray test resistance. As the world's best anti-corrosion technology in metal surface treatment, Dacromet technology is not only incomparable to hot-dip galvanizing in anti-corrosion, but also an environmentally friendly process technology, and its processing cost is only one-third of hot-dip galvanizing. Therefore, applying Dacromet technology to power fittings can at least double the service life of the fittings, and is beneficial to environmental protection and has good economic benefits. Therefore, the application of Dacromet technology in power fittings has great market potential.