What Are The Quality And Safety Requirements For Cross Arm Projects

When it comes to the engineering quality and safety requirements of crossarms, we have to mention the power fittings manufacturers. They have been producing tension wire clamps, galvanized crossarms, ball head hanging rings and other products for many years. They are very familiar with the engineering quality and safety requirements of crossarms. Here is an introduction:

The upper edge position of the top cap clamp: 10cm for straight poles, 15cm for tension, corner and terminal.

The position of the crossarm from the top of the pole downward: 60cm below the upper edge of the top cap clamp of straight poles, corner and tension poles, and 60cm below the crossarm of corners and branches.

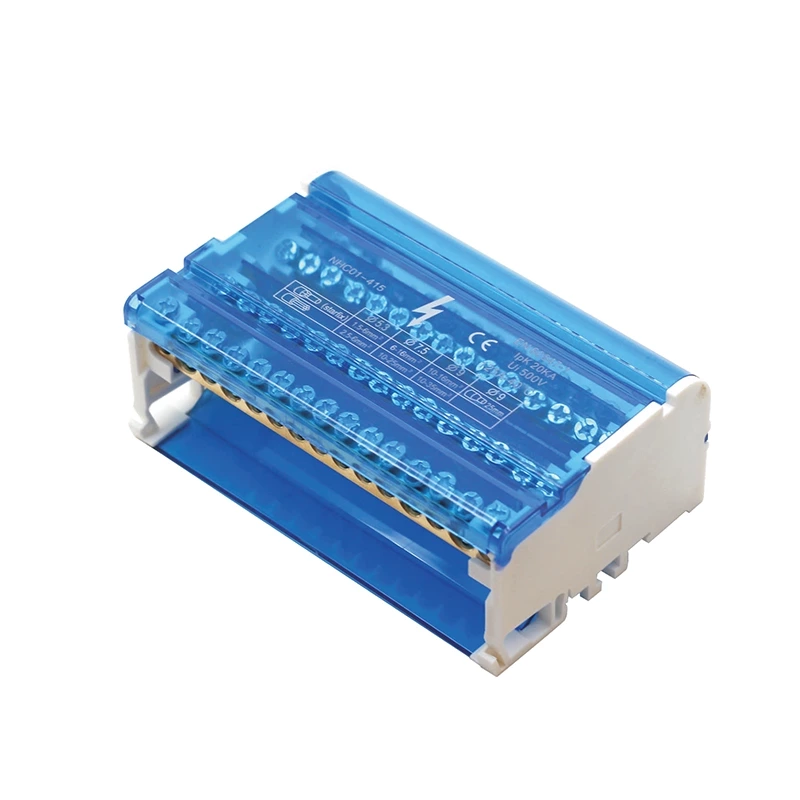

Two Pole Distribution Blocks: 80cm for straight poles, 60cm for tension, corner and terminal. Bolts such as crossarms, pull irons and hanging plates should be tightened. LJ-150 and tension, corner and terminal poles should be equipped with reinforcement bolts. The crossarm should be flat after installation, with ±20mm up and down;

Direction of the crossarm top cap: the straight pole is aligned with the direction of the line, and the corner and straight pole are aligned on the inner angle bisector.