What Needs Should Be Considered When Designing Terminal Blocks?

Terminal blocks are very versatile, so more consideration should be given to them when designing them. For example, in the power industry, the requirements for terminal blocks include: the edges and corners of the product shell, the burrs on the hardware, the connection strength of each component, and even the stability of the product under conditions such as movement.

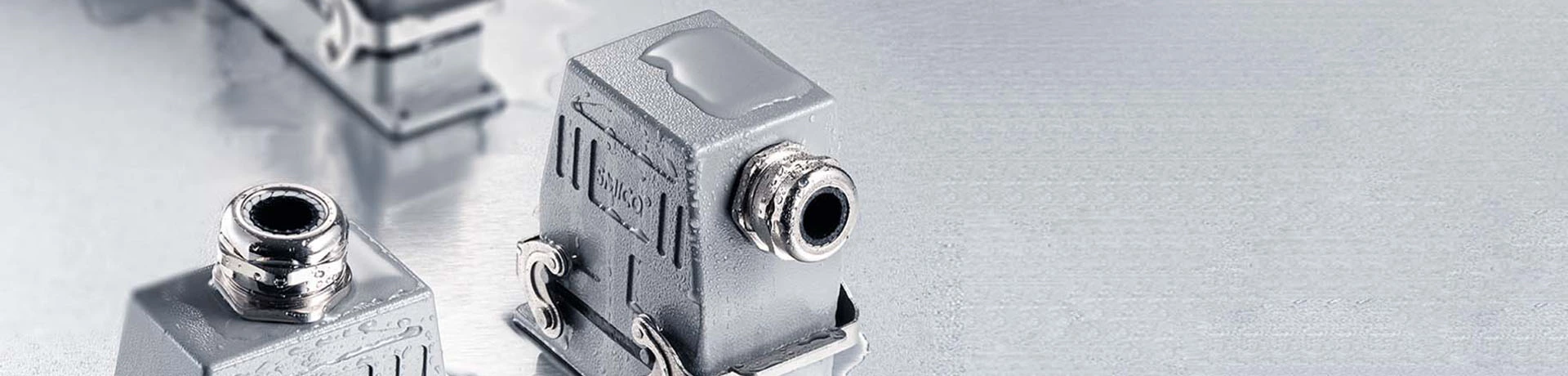

The Distribution box protection requirements of the terminal are mainly the provisions of JB/T 9568-2000 on the protection level, which is mainly divided into two types, one is the protection level of solid foreign matter, and the other is the harm caused by water to equipment and products. At the same time, regarding the insulation coordination of terminal blocks, it is often necessary to consider the material selection, working voltage, and environmental pollution level, determine the electrical clearance and creepage distance, so as to protect the safety of workers and products.

At the same time, it also prevents the product from insulation damage under overvoltage; in addition, the requirements of the tracking index should also be considered. During the use of the product, the surface of the solid insulating material forms a conductive path under the action of the electric field and electrolyte, thereby reducing the insulation performance of the outer shell insulation material and affecting the safety of the product.

The deformation of the material should also be taken into consideration, because the thermoplastic material mainly generates temperature rise and contact resistance in the work of the terminal. The high temperature caused by it causes the shell to deform and soften, thus causing electrical short circuit and serious accidents. Therefore, the selection of the material of the current-carrying parts of the terminal is very important.

When designing the structure of the terminal, the operating element should not be energized, and the terminal connected to the inside should not be accessible. This aspect mainly requires the reliability of the screw torque, and the screws and wires of the accessible terminals should be prevented from accidentally loosening and short circuiting.